The Comparison of Stamicarbon and Saipem Urea Technology

Introduction

This is the first part of a series of technical papers comparing Stamicarbon and Saipem Urea Stripping Technologies as per today (October 2016). With urea stripping technologies we mean urea melt technologies producing a urea melt suitable for prilling or granulation. This paper mainly discusses the latest process schemes applied in the high pressure synthesis section and medium pressure recirculation section as these are the two sections containing the major differences. But also peculiar differences in other sections will be highlighted. The paper will discuss the current and expected future developments in these process schemes for single line large capacity plants. Other future technical papers will focus on the applied materials of construction and typical failure modes, Safety Health & Environments aspects, operational aspects, revamp technologies and latest references. These papers will contain information as far as known in the public domain and reference documents are provided.

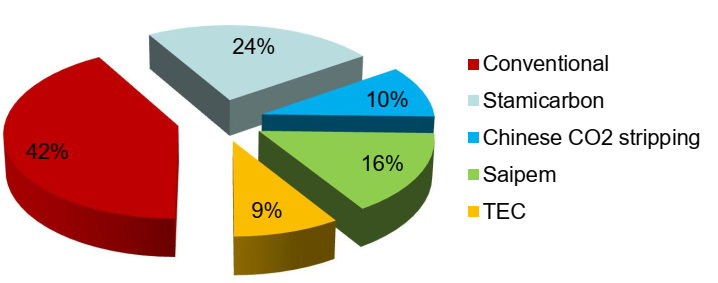

We focus on Stamicarbon and Saipem stripping process technologies as these represent the largest market shares today with respectively 24 and 16% of all urea plants in operation. Figure 1 shows the market shares of all urea process technologies of urea plants in operation in 2010. The CO2 stripping technologies resemble the Stamicarbon urea process with a falling film high pressure carbamate condenser.